Test Fixtures

SEA provides complete end-to-end HALT/HASS test fixtures solutions including board level, power supply and system level solutions.

Our text fixtures team will help you to:

- Develop a concept

- Provide a design

- Fabricate it

- Verify its operation

Additionally, we will:

- Provide all documentation to load the fixture in and out of the chamber

- Integrate the test supervisor with the unit under test (UUT)

- Run the fixture test

- Automate the test data collection

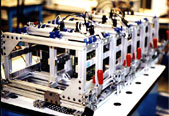

Fixtures

SEA designs fixtures using extruded aluminum to provide the best possible transfer of vibration and temperature with minimum mass.

To design a fixture, we will discuss your needs with you and provide a number of options before developing the final design. To create a final design we usually need a prototype of the UUT to make sure of its fit and function in the fixture and how it will work within the chamber you select.

We will then provide you with a final design that will allow you to review all of the salient features before we begin fabrication.

Once the fixture is built, we will verify that it conforms to the requirements of the chamber and the test function of the UUT.

Cabling

SEA can design and fabricate the electrical cabling necessary to provide the proper connections between the UUT and the test equipment.

Test Supervisors

SEA can develop an automated test supervisor (TS) that will control the power and monitor UUTs [NOTE: Please change “UUT’s to UUTs in titles]. The TS is a unique piece of test equipment that is specific to your UUT application. The development of the TS will require a functioning unit to verify its operation.

Software to Support the UUTs

Software is an integral part of testing solutions. The software can be written to turn power on and off, collect data, store data, and abort the test at a given yield threshold if desired.